Savings of 3 million tons of CO₂

Shaping a sustainable future – together.

Sustainability is the result of a holistic view on economic, ecological and social aspects – only those who fully understand this and take the necessary steps will successfully meet the challenges of the future. Our corporate strategy is built on the key aspects of sustainable management. Through certified environmental and quality management systems, we are implementing our sustainable strategy day by day. Every year, our lighting solutions save about 3 million tons of CO2 worldwide. Our whole product designing process is based on the premise to use as little resources as possible: in production as well as in daily operation of our products, thus creating “win-win” benefits – for our customers and society as a whole as well as nature and wildlife.

SITECO

Sustainability Report

Find out more about our sustainability commitment in our first Sustainabilty Report in accordance with GRI standards.

Download here

Sustainability strategy and goals

Our sustainability strategy is based on a materiality assessment that outlines the most significant sustainability issues that are

relevant to our business and stakeholders. SITECO's sustainability strategy focuses on the three key dimensions: People, Planet and Prosperity. To ensure the implementation of our strategic goals, we formed for each of the axes dedicated initiatives.

Prosperity

Circular economy accelerator with sustainable product offering

Product portfolio innovation: Development of intelligent lighting solutions

Footprint transparency: Full transparency on product-level sustainability along the life-cycle

Supply chain responsibility: Ownership for the supply chain exceeding legal requirements

People

lnvesting in our people

Employee health, safety and well-being: High employee satisfaction and zero accidents

Diversity and inclusion: Promoting an authentic, open-minded and inclusive company

Feedback and continuous development: Entrepreneurial mindset by empowerment and development

Planet

Reducing energy consumption and emissions

Energy efficiency: Reducing our customers’ energy consumption and CO2 emissions by improved equipment and processes

Reducing emissions and air pollution: Reducing emissions in core and adjacent processes

Circularity: Increased use of renewables and building up recycling capabilities

Our commitment to the Sustainable Development Goals

The United Nations’ (UN) 2030 agenda consists of a global plan promoting sustainable peace, prosperity and protection of our planet. From 2015 onwards, public and private corporations are working towards this agenda along 17 Sustainable Development Goals (SDGs). As part of our sustainability strategy and to use our resources effectively, we decided to focus on a subset of 11 SDGs on which we have the strongest impact through our entrepreneurial actions. Our sustainability refers to the specific SDGs which SITECO is pursuing.

EPDs

External certified Environmental Product Declarations (EPDs), underline our commitment to transparency and sustainability. EPDs provide verified information about the environmental impact of our products, empowering customers to make informed, eco-conscious decisions.

- No light pollution: Zero percent light in the upper atmosphere for an insect-friendly dark night sky.

- Targeted lighting control: SITECO luminaires can be dimmed, activated and controlled as needed.

- Convenient separation: Easy separation and returning to the material life cycle.

- Environmentally friendly production and packaging: SITECO follows environmental protection guidelines for its production operations in Germany.

- Sustainable light: Everything at SITECO is designed with long-lasting operation and significant CO2 savings in mind.

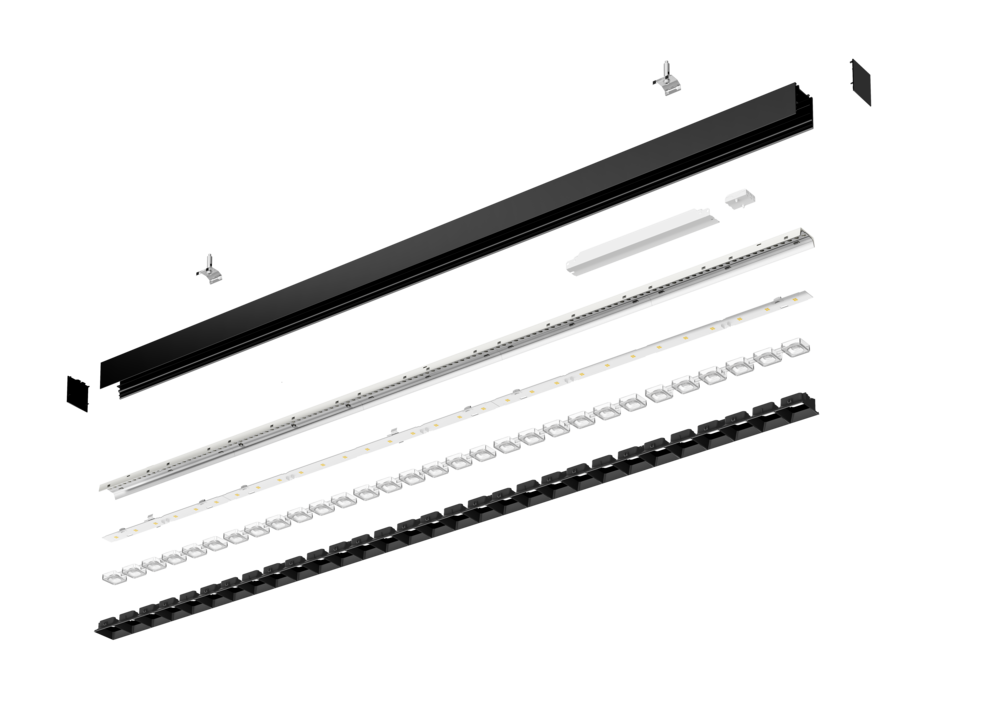

- Future-proof and tool-free maintenance: Easy upgrades and repairs due to clever modular concept.

- Environmentally friendly production: Selected materials, minimal material input, Made in Germany.

- Recycling: 90% of thematerial can be used to bring a new luminaire to life.

- Modular products: Modular system for exceptional longevity: repairs and upgrades in no time at all.

- Security for the future: Rigorous gear tray principle: Separation of housing and inserts means components are interchangeable.

- Putting the focus on people: Human centric lighting (HCL) is at the core of user-oriented light. This ensures lighting only when, and in the amount, needed.

- Focus on energy efficiency: Focus on eco-design throughout the entire life cycle aiming for the highest level of energy efficiency.

- Luminous efficacy of more than 200 lm/W to keep the CO₂ footprint as low as possible over the service life.

- Reduction of CO₂ emissions by up to 90 %

- 100 % future proof: We are continuously developing refurbishment KITs that can be easily integrated into our fixtures and thus continue to use existing housings.

- Saving up to 75 % Energy and CO₂ emissions.

- Up to 90 % of the old luminaire is retained, making it as sustainable as possible.

- Environmentally friendly production “Made in Germany” That means: No long transport routes that stretch halfway around the globe.

- Constantly assessing potential insourcing of processes to limit the environmental impact.

- ~100 t CO₂ savings on transport emissions p.a. by insourcing of manufacturing process from Hungary and Slovenia to our HQ in Germany.

- Exceptional lighting technology for light only where and when it is needed – for maximum environmental protection.

- Warm light colors: SITECO also offers warm light colors that attract less nocturnal insects.

Certificates and guidelines

SITECO has a large number of guidelines and certifications to ensure sustainable behavior.